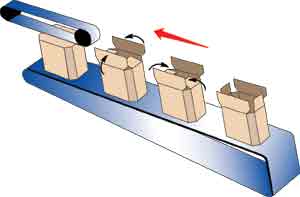

The productivity of a packaging line is directly related to the quality of case erection. Formation of the die-cut blanks around a mandrel and synchronisation of movement by the cams guarantee reliability of Otor Systems' case erectors.

1 -Transfer of die-cut blank from magazine

2 -Converydie-cut blank under mandral

3 -Gluing of die-cut blank during transfer

4 -Erection of cut blank around mandrel

5 -Pressing manufacturer's joint and four bottom flaps

6 -Ejection of formed box

Otor Systems closers can be easily incorporated into packaging lines for

all types of cases with flaps :

they can be used for both standard cases and more innovative boxes such as

Otor 4 and Otor 8

1 - Arrival of filled, open cases on spacing conveyor

2 - Spacing of cases on main conveyor belt

3 - Conveyance by main belt with guidance of bottom of the case and two sides

4 - Folding of small flaps

5 - Simultaneous pre-folding of long flaps by ramp

6 - Hot melt gluing of small flaps

7 - Pressing of glued flaps

8 - Ejection of closed cases

(the case is guided to the machine outfeed).